and the tiller work continues. I found a piece of suitable oak with a decent sweep to the grain in the wood shed. Tom thinks it may be Black Oak. Not as durable as White Oak but will serve well as a tiller. Looks like it will take a nice finish.

Being this close may justify bending on the sails and thinking about actually sailing.

…

Just another coat of bottom paint and it’s done.

…

From the left: the original tiller from 1985, the pine pattern and the oak blank. Should be close to the original but a bit longer. Phil Bolger observed that a longer tiller generally makes for a better sailor. We’ll see.

…

One needs nourishment for the shaping of the tiller. Cozy below as always.

…

Rainy day at Beaton’s. Taken from the wood shop after a watch below on Sjogin.

…

Here’s a pair of fifty foot Skita Spruce 1 X 10s. Ready to be sliced up and turned into a new Birdsmouth spar for Ghost. Looks fast Bill!

…

Myth’s in the shop for a new deck. The old one suffered from melting deck seams on hot days. The new one will be teak over ply.

…

Another ice free, high water, calm day perfect for drifting about. I know as soon as she’s back in commission the weather will revert to mean.

…

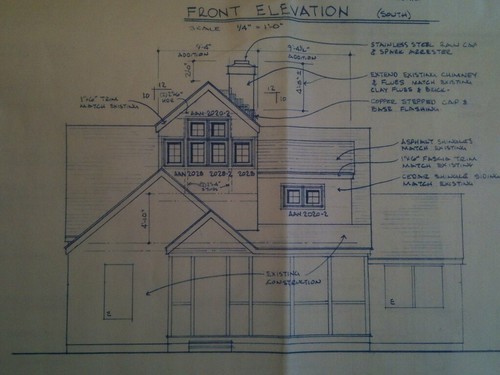

After 23 years we’re about to have a better view of Stockton Lake and more importantly, the Atlantic, from Ourhouse.

…

…